I got them free from the local rock quarry. Had a bunch of them sitting there not knowing what to do with them. Also got some free from the local tire supplier... take off discards from another rock quarry. Cost's them money to dispose of 'em, so they're not hard to come by. The big payloader tires or earthmover tires are best... way heavier than like a tractor tire. Takes some work to sawzall the bead off the one side, but I was able to do it in about a half hour with a new blade. These are 3' wide by 6' diameter... figures out to about 600 gallons. I've got 280 head on them, and I've never seen them drop more than about 6". Wintertime though... probably drink alot faster in the summertime! I'd say get as big of ones as you can get your hands on... or as big of ones as you are comfortable hauling...

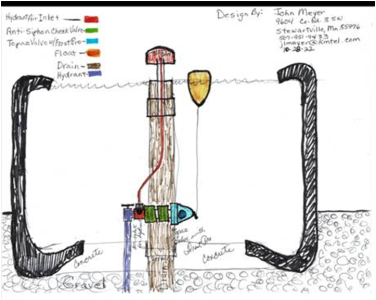

If you're going to do the continuous flow for winter, be sure to put in an adequately sized drain... it can just go off into a ditch or something, and doesn't have to be buried very deep at all... just enough so the cattle won't get at it when it's muddy. You should put a drain in any way, so you can drain and clean the tank, but for continuous flow, you need to put a standpipe on the drain (so it drains off the excess off the TOP while the tank is full). I put a 4" PVC FPT fitting level with the top of the concrete floor, and then threaded a 4" MPT fitting into that, with the riser pipe glued into that fitting. Then just cut it off at the right height, and stick a 4" PVC vent stack screen into it to keep the hay from going into your drain. To drain the tank, just unscrew the riser pipe.

A friend of mine used a brass "bleeder valve" for the continuous flow... like a needle valve. Only need about 1/8" hole for flow. He put his so it kind of circulates the water in the tank as it comes out of that valve... I don't think that's what's keeping it open though... it's just geothermally heated water (ground heat) coming into the tank, rising to the top, and going out the overflow. The colder it gets, the more "inflow" you will need to keep it open.