Welcome to the future.

A factory in The Netherlands 3D prints 500 tons of steaks a month. Redefine Meat company will supply German restaurants with printed fillets.

Approximately 110 German restaurants are already buying "meat" from Redefine Meat.

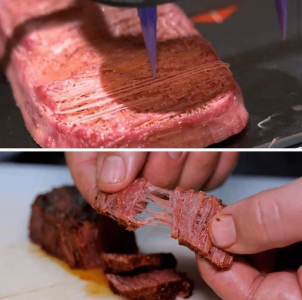

"To begin the 3D-printed meat process, scientists biopsy a batch sample of animal stem cells depending on the desired type of meat — beef, pork, poultry or even fish. These cells then undergo an in vitro proliferation process, bathing in a nourishing, nutrient-dense serum within a climate-controlled bioreactor.

Over the course of several weeks, these cells multiply, interact and differentiate into the fat and muscle cells that make up bio-ink. Then, a robotic arm uses a nozzle to dispense this paste-like, cultured meat filament in fine layers atop one another. The arm follows the instructions of an uploaded digital file using computer-aided design, or CAD, software in order to replicate the correct shape and structure of the intended meat. 3D-printed meat material must be viscous yet firm enough to reproduce a structural model complete with accurate tissue vascularization, depending on the type and cut of meat."

Written by Brooke Becher Aug 09 2023