alacowman1

Well-known member

- Joined

- Sep 30, 2020

- Messages

- 1,427

- Reaction score

- 2,800

Last edited:

I'm in concrete construction, buddy of mine was washing up his concrete pump, cleaning the hopper. Pump was running and when he bent over to dig out some gravel he hit his remote control and cycled his pump. Cut his hand off at the wrist. Very gruesome event. Only takes a second.Had something happen yesterday, was unhooking bushhog ,and layed the adjustable arm pin on the fender..as i was reaching down too release the pto shaft..the pin rolled off the fender and hit the pto engagement lever.. I was In between tractor and hog. Blades turning right next to my feet .plus the thought of what could have happened if it's was a second later, with my hands on the pto coupling..

Sensible pto's are one of the biggest killers in farming and agriculture has one of the biggest accidents/ death rates of all sectors (in my country at least) more so than construction which has really improved its standards. I really think people should keep pto guards on. I did an awareness course aboyt ten years ago and the accident death rate was about 50/ yr so times that by six possibly to get the US figure.I simply will not get out of the tractor seat if the pto is engaged. The only time that shaft is turning is when my butt is in the seat.

That is bad luck. Hindsight is always 20/20 but that is why I turn the tractor off when I get off a lot of the time. Between the ag world and o&g I've just seen too many freak things like that. Most of the time I am/ was by myself in both applications and even with a freak accident, I would be lucky if some one gets to me in time. It has made me bordline paranoid.Had something happen yesterday, was unhooking bushhog ,and layed the adjustable arm pin on the fender..as i was reaching down too release the pto shaft..the pin rolled off the fender and hit the pto engagement lever.. I was In between tractor and hog. Blades turning right next to my feet .plus the thought of what could have happened if it's was a second later, with my hands on the pto coupling..

o&g=oil and gas..Between the ag world and o&g I've just seen too many freak things like that.

Took for granted ,something I've done a hundreds of times unhooking and moving to another implement the spray rig..getting in a hurry before the wind picked up..That is bad luck. Hindsight is always 20/20 but that is why I turn the tractor off when I get off a lot of the time. Between the ag world and o&g I've just seen too many freak things like that. Most of the time I am/ was by myself in both applications and even with a freak accident, I would be lucky if some one gets to me in time. It has made me bordline paranoid.

We have all been there. We still have tractor we use for mainly hay now you have to start with starting fluid and probably jumper cables. It will start in gear too. No parking break. I hate it. It's been like that all my life.Took for granted ,something I've done a hundreds of times unhooking and moving to another implement the spray rig..getting in a hurry before the wind picked up..

People love to leave the belt guards off on pump jacks also.o&g=oil and gas..

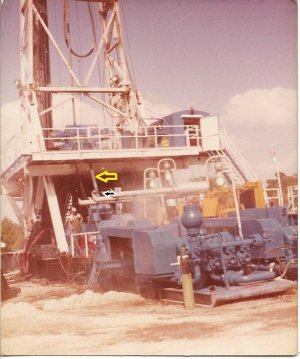

Look at this OIME brand drilling rig from the late 70s/early 80s..built out in Midland/Odessa with three 3412 Cat engines for power.. it's selling point was quick rig up and rig down. Instead of diesel electric or scr or even a shielded chain and sprocket drive going up to the floor, it used a 6 or 8" diameter drive shaft and Ujoints going up to the floor to power the rotary and draworks. It came with a big guard over the drive shaft (yellow arrow) that covered every bit of it from right angle drive up to the draworks but if you look at the picture, the black and white arrow points to the exposed universal joint, meaning the guard was left off.

View attachment 31857

Gotcha. Father in law had a 766 at one time and I seem to remember it having a similar setup, not exactly the most ergonomic deal.It's an old IH 664 the lever is back on the left side ..you can see the lever sticking up left hand side ,between the fender and seatView attachment 31855

WOW.Had something happen yesterday, was unhooking bushhog ,and layed the adjustable arm pin on the fender..as i was reaching down too release the pto shaft..the pin rolled off the fender and hit the pto engagement lever.. I was In between tractor and hog. Blades turning right next to my feet .plus the thought of what could have happened if it's was a second later, with my hands on the pto coupling..

I've become a bit pedantic these days about putting my seatbelt on too. I don't trust myself not to fall asleep.I simply will not get out of the tractor seat if the pto is engaged. The only time that shaft is turning is when my butt is in the seat.

We had a discussion on here about standing under a FEL a few years ago. A state trooper from this area was under one and a hose gave out and it fell and crushed him.Man here back in May was spraying hay field, alway goes wide open..Hit a small sink hole that wasn't there last year, they said..front wheel like too have thrown him off ..back wheel went in and off he came..nearly got free when the rear tire grabbed his carhart jacket, the back tire literally chewed his left arm off above the elbow, as it was stuck still turning in the hole..flew him too UAB where they removed left arm, and repaired his crushed right hand, when he was trying to free himself..