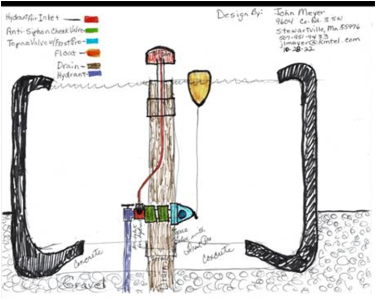

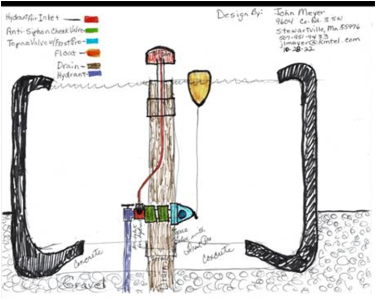

That 4" white PVC pipe in the center is the overflow drain, which drains off the excess. Where that comes up through the concrete floor, I put a 4" PVC FPT fitting (top of it level with the top of the floor). The standpipe for the overflow has a 4" PVC MPT fitting screwed into that first fitting, with a 4" PVC pipe glued into it, and cut to length

just above where your full height water level is from the float-controlled valve. I stuck a 4" PVC vent stack screen into that pipe then, to keep hay etc. out of the drain. The drain line is connected to my field tile, and eventually exits into a creek. It can just run off into a ditch somewhere too of course... but obviously you want to get it away from where the cattle will be congregated. To drain the tank, just unscrew the standpipe.

The well won't be "constantly running"... but it will of course be running intermittently, cycling off and on, just like it does anytime you take water from the system. The amount of "continuous flow" required is pretty small (only a small 1/8" tube coming out of the "FrostPro" valve, which is inserted into a Jobe Topaz float-controlled valve... this is the same as their MegaFlow, but the Topaz has a port built into its valve body specifically for the "FrostPro", which allows for some minimal continuous flow). So no, I'm not concerned about "burning up the well pump", or overworking it. Obviously, everything has a lifespan, and yes, the more water you pump, the sooner you'll of that lifespan and have to replace your pump... but that applies to everything that you pump water for... how many cattle are you running that you're going to be watering then too... or how many people you have at your place, or how many sprayer refills you need to do every year, etc.

The more "continuous flow waterers" you have on your system, the more your pump will have to be running of course too. However, if you've set them up right,

you DON'T have to keep them ALL running all the time. These CAN freeze over without damaging anything... the tire tank itself won't be damaged, even if it gets like 12" thick ice on it. The inlet valve is on the bottom of the tank, like 20" below the top waterline. Beyond that, I used a "utility hydrant" (stated above in a previous post,

Woodford-U125M-2-Product-Overview.pdf) as my water inlet shut-off, so I can actually

shut the water off below frostline, if I want to (proper functioning of that hydrant then requires the use of an "air valve" (

S-050 | Automatic Air Release Valve "Segev" (arivalves.com))

with a snorkel on it, which I also put on these... so the hydrant can draw air in to drain down, while the tank is still full of water...).

That "air valve" is followed by an anti-siphon check valve (you NEED this also for the hydrant to function properly when draining down, but you SHOULD have one of these on any underwater tank valve anyway), to keep water from the tank from being able to move backward into and potentially contaminating the supply line, and then comes the main float controlled valve with the "FrostPro". Everything is positioned well underwater, protected from freezing. You can shut off the water coming into the tank if you want to or just shut off the "FrostPro", and still keep the tank full of water and let it freeze over. When you need it because you've moved the cattle to another area, for example, just chop the tank open, and turn on the "FrostPro"...

Remember that the "FrostPro" valve IS

at the bottom of the tank though... so you'll be reaching down through a full arm's length of water to manipulate it... unless you drain the tank. If it's below 0 when you need to do this, it's going to be just a bit chilly!

It's cheaper to pump a little more water, than it is to try to heat a tank to keep it open. Geo-thermally heated...

Here's a diagram of the installation... I show two check valves on it... that's just as insurance in case one would fail. One should do it, and is all I used.

If you're on a municipal water supply, these check valves might not meet your code requirements, and you might HAVE to have an air gap  ... check your local regulations.

... check your local regulations.