skyhightree1

Well-known member

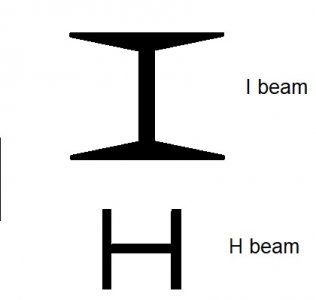

I decided not to buy a new soil pulverizer for 75k ok I'm exaggerating but I need another pulverizer and something to do mayb build with my son he's interested in welding and going to take it in tech next year. I have everything except bearings and springs to build it I think. My question for y'all is I have a 3 inch pipe I'd use as a roller with the spikes on it. Since I was going to use everything on hand I was going to put concrete in the pipe for added weight to bust dirt clods. I also figured if I just use cement for the weight I won't need a spring for down pressure but allow it to move up and down with land contour. I have a H beam it's 3/8" I think. I forgot too measure but the others I've seen were 1/2 inch I thought about putting cement in the frame to make it heavier. What do y'all think.