Chapin81

Well-known member

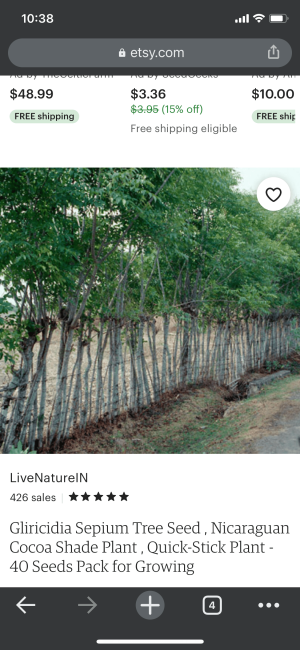

hi everyone, I'm trying to lower my cost because ever since January I've spent out the wazooo in either upgrades or things that are necessary for the cattle operation to move forward. As some of you know we are located in Guatemala I'm in NYC. Our pastures are divided with either barb wire and wooden post that are 12-13 years old or barbwire with wooden post and a tree called Gliricidia Sepium sometimes called quick stick, back home we call it madre de cacao. These tree takes a few years to grow but it becomes a great "living fence" this is a common practice down there to avoid unnecessary spending on wire and post in the future. I want to run hi tensile wire as some of you have recommended so I can practice rotational grazing the hi tensile was supposed run on the original fences however most of the post are rotting or the quick stick isn't thick enough for an insulator, buying wooden post has gone up in price significantly. I found these Zareba screw on insulators, in the pic it's mounted on rebar up to half inch. I was thinking of maybe running the hi tensile with the rebar 6-12 inches in front of our permanent fence and maybe 5 ft in height. Has anyone done this?? How long would rebar last buried into the ground? What if I throw some cement in there so the soil doesn't eat away the metal??how far apart can I place the rebar?? I really only need it to hold the hitensile because the real fence is behind that hitensile. I was looking into buying fiberglass rods but to ship them it's going to cost an arm and a leg, buying down there isn't an option everything is so darn expensive. I just purchased 5 plastic Gallagher handles down there to tie at the ends of the turbo wire at $12 each plus shipping! Btw rebar is costing $5.50 per 20ft rod 1/2 inch. Wooden post are costing $5 per post. The trees below are not mine, it's just a pic I took of the internet to show what it looks like.

Thanks in advance for any suggestions or advice.

Thanks in advance for any suggestions or advice.