Hay equipment question. My vermeer trail mower has been giving me some problems (it took a complete dump and has probably only cut 400 acres so the local dealer completely rebuilt it according to them at about $4,000 and then the rebuils lasted about 10 acres on saturday and the cutter bar and gears again have a huge problem) and I'm beginning to doubt the ability of it to last very much longer so I've started shopping around. I'd like some thoughts on a cart and a disc mower vs a trailed mower, I've never used a carted cutter but I'm not a big fan of hanging a 10' mower off the back of a tractor. Is it as fast, does it cut as well, what are your thoughts. Also have a question to the Krone users, are they really worth the difference in pricing from a Kubota or Kuhn cutter?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hay Equipment question

- Thread starter Stonewall Joe

- Start date

Help Support CattleToday:

Stickney94

Well-known member

Have never heard of a trailed mower -- a little different than a mower conditioner which are abundant here. Are you cutting fields? Ditches? Nice flat rectangles or hilly polygons?

I've found Kuhn mowers to be very durable -- but if your local dealer has Krone parts/service that might justify any price differences.

I've found Kuhn mowers to be very durable -- but if your local dealer has Krone parts/service that might justify any price differences.

I think he means towed mower. Not 3pt hitchHave never heard of a trailed mower -- a little different than a mower conditioner which are abundant here. Are you cutting fields? Ditches? Nice flat rectangles or hilly polygons?

I've found Kuhn mowers to be very durable -- but if your local dealer has Krone parts/service that might justify any price differences.

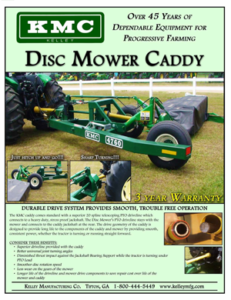

A trail mower is one that looks like a mower conditioner but there is no conditioner, just a 10' disc mower in the frame. In my opinion after years of just using a standard 3 point disc mower it follows the terrain better and all it does on the tractor is attach to my draw bar as far as weight goes and is pretty fast. A carted (some call the cart a caddy) mower is a 3 point mower that is supported by a 3 wheel cart to get the weight off of the tractor and follows behind. Also with a trail mower you can use the hydraulic swing to put the mower to the side or straight in line behind you. The Kuhn cutters I've had were pretty reliable, I like the 3 blade mower philosophy but I've never had one and the Krone looks a lot more substantial but costs a lot more. My hay fields are not real big and are not that hilly, 2 have kind of rolling hills. We only put up about 25 acres or so at a time and the fields are clean with no debrisI think he means towed mower. Not 3pt hitch

Attachments

Hogfarmer10

Well-known member

My only experience is with a 3pt mounted disc mower but my thoughts are:

1.Cost of trailed mower vs cost of caddy and mower. With a caddy, I'm going to say it will outlast the mower, so probably would be able to just replace mower if necessary. But, I've also not seen a caddy that was built as heavily as the framework of a trailed mower.

2. I think you will have more consistent results with the trailed mower. Probably less "little minor adjustments" to be made with the trailed mower.

3. This is a peeve of mine but if you store you're equipment inside, which one takes the most space.

Either option will mow hay. I guess I look at it as 2 machines vs 1. Mower + caddy or just the mower. Unless caddy is same brand or from the same dealer, does that mean 2 different places to get parts?

Sorry for the aimless rambling.

1.Cost of trailed mower vs cost of caddy and mower. With a caddy, I'm going to say it will outlast the mower, so probably would be able to just replace mower if necessary. But, I've also not seen a caddy that was built as heavily as the framework of a trailed mower.

2. I think you will have more consistent results with the trailed mower. Probably less "little minor adjustments" to be made with the trailed mower.

3. This is a peeve of mine but if you store you're equipment inside, which one takes the most space.

Either option will mow hay. I guess I look at it as 2 machines vs 1. Mower + caddy or just the mower. Unless caddy is same brand or from the same dealer, does that mean 2 different places to get parts?

Sorry for the aimless rambling.

the trail mower has been excellent when it works, super easy to hook up and use, cuts great, but again that's if it works. When it was new we had one old t post on the whole damn place and it hit it on it's second use, not the mowers fault and we had been cutting that patch for 5 years ut since I bought it at the same time as the kubota tractor it came with Kubota insurance so they fixed it for free, we only cut about 25 acres usually 3 cuttings a year so that was about 7 years ago, that's not much hay and it went out on it's own, it hit nothing but grass so we had it rebuilt and after 10 acres of grass it went out again so now I'm kind of shy with it so like I said I'm worried. I'd just like it to be as dependable as the old Kuhn cutters which gave us almost no problems although were not as fast so when it's time to cut we just check the grease in the blade bar and gear box and go because we do all our other maintenance when we get done cutting

Hogfarmer10

Well-known member

I'm somewhat surprised about the performance of your mower. I'm on my second Vermeer 3pt disc mower and have been extremely pleased. My first one lasted 14 years of mowing 400 acres at least 2x per year, sometimes 3. Had a 9', went to 10'. (8040). I agree about it being a lot hanging on the back of a tractor. I mow with a Ford 7700 2wd open station (85 pto horsepower) and I've never needed more power but there are times I've really wanted more counterweights!

What is happening when your cutterbar "goes out"?

We've got 2 Vermeer discbines, and old 7120 that's at least 25 years old and Lord knows how many acres it's cut. Even cut a t-post off flush one night and ran it through the steel rollers in 2 pieces - didn't hurt a thing other than the t-post. I picked up an 840 a few years back and kept the 7120 as a backup/2nd cutter in big fields.

We've got 2 Vermeer discbines, and old 7120 that's at least 25 years old and Lord knows how many acres it's cut. Even cut a t-post off flush one night and ran it through the steel rollers in 2 pieces - didn't hurt a thing other than the t-post. I picked up an 840 a few years back and kept the 7120 as a backup/2nd cutter in big fields.

Well I've had the 3 blade Vicon, which is now the Kubota. It's a good cutter that lasted many years an cut good.

When I replaced it I researched, asked commercial cutters. Pretty much everyone said ther two best are Kuhn and Krone.

My dealer happens to sell both and they were about the same price. My Uncle also has one of each.

I went with the Krone and am very happy. Nice even cut, quick change blades, and no belts.

Btw my uncle uses what I think is a vicon blade on the Kuhn, and it improves the cut.

When I replaced it I researched, asked commercial cutters. Pretty much everyone said ther two best are Kuhn and Krone.

My dealer happens to sell both and they were about the same price. My Uncle also has one of each.

I went with the Krone and am very happy. Nice even cut, quick change blades, and no belts.

Btw my uncle uses what I think is a vicon blade on the Kuhn, and it improves the cut.

the cutter was cutting just fine like it was supposed to do, then there was a loud rattling noise and although the gear box was working the heads stopped moving. On examination you can see where the heads closest to the gear box jumped time and hit each other which I assume was the noise, then it stopped cutting. The only heads that now turn in time with each other are when you hand turn the final 2, the others only turn one at a time as if the driver has completely been disconnected and when you turn them by hand there is no resistance, they just free turn. I've had vermeer equipment in the past with virtually no problems but this one has had issues. This has been a year for problems with equipment it seems, we finished up cutting with my old Kuhn cutter which even after 25 years cuts like a champ and yesterday the clutch on the pick up reel of my Kubota round baler went out after about 35 rolls/. To help avoid problems we had just taken the baler to the Kubota dealer to have completely gone over but I guess they don't look close enough. After years of Vermeer and John Deere balers the Kubota "Premium" baler has been a disappointment. My son is going to get the New Holland square baler out and bale part of it today and the neighbor is coming over to roll the restWhat is happening when your cutterbar "goes out"?

We've got 2 Vermeer discbines, and old 7120 that's at least 25 years old and Lord knows how many acres it's cut. Even cut a t-post off flush one night and ran it through the steel rollers in 2 pieces - didn't hurt a thing other than the t-post. I picked up an 840 a few years back and kept the 7120 as a backup/2nd cutter in big fields.

M.Magis

Well-known member

Is the dealer that "went over" the baler the same place that rebuilt the mower? Really sounds like the issue stems from the T post incident and perhaps a poorly done rebuild?

++++1A trail mower is one that looks like a mower conditioner but there is no conditioner, just a 10' disc mower in the frame. In my opinion after years of just using a standard 3 point disc mower it follows the terrain better and all it does on the tractor is attach to my draw bar as far as weight goes and is pretty fast. A carted (some call the cart a caddy) mower is a 3 point mower that is supported by a 3 wheel cart to get the weight off of the tractor and follows behind. Also with a trail mower you can use the hydraulic swing to put the mower to the side or straight in line behind you. The Kuhn cutters I've had were pretty reliable, I like the 3 blade mower philosophy but I've never had one and the Krone looks a lot more substantial but costs a lot more. My hay fields are not real big and are not that hilly, 2 have kind of rolling hills. We only put up about 25 acres or so at a time and the fields are clean with no debris

I have cut all three ways. 3-point disc mower, trailing mower/conditioner, and docs mower on a caddy. If you do not meds a conditioner, a disc mower on a caddy is by far the most flexible, mobile way to go. If you have to travel from field they are quicker. I would say as long as you are doing a 10' or less cut a disc mower & caddy is best.

Farmerjon

Well-known member

Stonewall, I am not aware of your experience, those on here that have similar equipment but way different results,, might discuss ground speed (gear) and rpm's. Maybe you are running it to fast and it is beating itself up? I do not know, but that might give more insight and help with keeping it together and working properly.

Exactly.Is the dealer that "went over" the baler the same place that rebuilt the mower? Really sounds like the issue stems from the T post incident and perhaps a poorly done rebuild?

The individual pods are connected by a hex drive shaft in the back of the pods. I'm betting the post broke the internals (a drive and a driven gear, and bearings if memory serves me correctly) of one or two pods and severely damaged the hex drive shaft. Again speculating, but it would have been easy to repair the pods and overlook the driveshaft - which in turn would fail as soon as sufficient stress was introduced to the shaft. The shaft is currently toast if the pods act independently of one another.

Take that as you will, internet diagnostics from x miles away are worth exactly what you paid for them.

Edited to add: I just went back and read where there was a significant time lapse between the 2 events, my apologies. Either way, I'd bet money your hex shaft is trashed and wasn't properly installed during the rebuild.

hurleyjd

Well-known member

I think I would ask the dealer to do the job over. Someone in the shop did not get something right.Hay equipment question. My vermeer trail mower has been giving me some problems (it took a complete dump and has probably only cut 400 acres so the local dealer completely rebuilt it according to them at about $4,000 and then the rebuils lasted about 10 acres on saturday and the cutter bar and gears again have a huge problem) and I'm beginning to doubt the ability of it to last very much longer so I've started shopping around. I'd like some thoughts on a cart and a disc mower vs a trailed mower, I've never used a carted cutter but I'm not a big fan of hanging a 10' mower off the back of a tractor. Is it as fast, does it cut as well, what are your thoughts. Also have a question to the Krone users, are they really worth the difference in pricing from a Kubota or Kuhn cutter?

I'm not much of a race driver when it comes to putting up hay, after years when I was young working on my grandad's place who had older equipment and then my place cause all I could afford was old equipment I learned that slower is usually faster. I also tend to run a little under 540 on the RPM's, not a lot but a little and I listen to my equipment, if I hear it in a bind I back off so I don't think it's that and we've worked hard at keeping the hayfields clean and pretty smooth but out of all of the equipment I've owned over the years I have to say I've had worse luck with our current equipment bought new than with some of the old stuff we could just scrape together. Maybe it's just me getting older and persnickety and spending a lot more money than in the pastStonewall, I am not aware of your experience, those on here that have similar equipment but way different results,, might discuss ground speed (gear) and rpm's. Maybe you are running it to fast and it is beating itself up? I do not know, but that might give more insight and help with keeping it together and working properly.

The cutter is back in the shop, they are going to redo it for free, maybe it was just a simple mistake. I really hope it was.I think I would ask the dealer to do the job over. Someone in the shop did not get something right.

I would bet the shaft is trashed as well but when they told me why the rebuild was so high they said they had to put a new one in, maybe it's just "one of those things" or maybe their techs aren't to great on equipment although they can work on tractorsExactly.

The individual pods are connected by a hex drive shaft in the back of the pods. I'm betting the post broke the internals (a drive and a driven gear, and bearings if memory serves me correctly) of one or two pods and severely damaged the hex drive shaft. Again speculating, but it would have been easy to repair the pods and overlook the driveshaft - which in turn would fail as soon as sufficient stress was introduced to the shaft. The shaft is currently toast if the pods act independently of one another.

Take that as you will, internet diagnostics from x miles away are worth exactly what you paid for them.

Edited to add: I just went back and read where there was a significant time lapse between the 2 events, my apologies. Either way, I'd bet money your hex shaft is trashed and wasn't properly installed during the rebuild.

Actually a different dealer but the old place went out of business and all of their techs went to the new place. I would bet on a poor rebuild after the baler incident and their baler workIs the dealer that "went over" the baler the same place that rebuilt the mower? Really sounds like the issue stems from the T post incident and perhaps a poorly done rebuild?

We have a MC840 that has a history pretty similar to yours. Hit something and it will break the gears in the cutterbar, if you're lucky the upper gear only, but it has broken several lowers and the whole cutterbar needs to be disassembled to repair that. I've gotten pretty quick with it, on ours I can drop one side of the cutterbar and have it slid apart in an hour or so.

CFpinz is correct with how that cutterbar is driven. On a 10' mower I believe there are three hex rods that connect each group of pods. It's very possible that the impact partially sheared the corners off of one end and the dealer missed it during reassembly.

Last year we upgraded to a NH DB313R. There are things I don't like about it's cutterbar, but at least it has a shock hub that isn't too bad to swap out if you hit something.

Krone has the best shear protection IMO, they use a threaded spindle and a roll pin. If you hit something the pin will shear and that turtle will unscrew out of the way so the adjacent ones don't beat it to death.

I believe Kuhn's setup breaks the whole turtle off and throws it out the back, which works I guess but doesn't seem like the best way to me.

CFpinz is correct with how that cutterbar is driven. On a 10' mower I believe there are three hex rods that connect each group of pods. It's very possible that the impact partially sheared the corners off of one end and the dealer missed it during reassembly.

Last year we upgraded to a NH DB313R. There are things I don't like about it's cutterbar, but at least it has a shock hub that isn't too bad to swap out if you hit something.

Krone has the best shear protection IMO, they use a threaded spindle and a roll pin. If you hit something the pin will shear and that turtle will unscrew out of the way so the adjacent ones don't beat it to death.

I believe Kuhn's setup breaks the whole turtle off and throws it out the back, which works I guess but doesn't seem like the best way to me.