Odd this came back up today. I intended to go take another look at it but the neighbor told me it started working right so I never did, but just tonight, he told me it had started doing it again about a week or 2 ago and his elec bill was sky high.

I think JD may be correct about the line inside the tank. Evidently, this problem has existed since mid summer. Last years extreme cold, coupled with a long period of no electricity may have caused it.

The water in the storage tank never froze other than about an inch of ice on top. He would open a valve down on the output side, and draw off water for flushing their toilet and cooking. I surmise, that there is a footvalve in the bottom of the submersible pump and water stayed in both the pump and in the PVC line coming out of the pump. That pvc line may very well have frozen since it was exposed as he drew water out of the tank. Water coming out of a well here is the same constant ~70 deg year round.

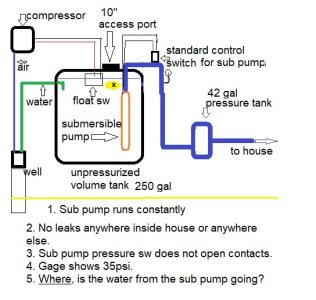

We had warm weather all the way thru December 2021. In Jan, it started getting cold. It may be, that the line just above the pump but below the normal water level cracked last year. In warm weather, the crack opens because the water and the line are relatively warm, the line pressure never quite reaches the turnoff pressure and pump runs 24/7 but when it got cold not long after I posted this thread, the water in the tank decreases in temperature, the pipe contracts in diameter and the crack closes up enough for the system's pressure switch to start turning on and off. The crack would have to be below the water line or I would have seen it and heard it spraying when I looked at it.

The crack would have to be in the area where the yellow arrow with the black x indicates.

View attachment 12972

The reasoning I was given for this setup is for easy maintenance and cheaper operation. There is virtually nothing downhole to wear out. No pump to pull out of the bottom of the casing, no long electric cable to break or corrode. No high head of water to lift with a pump downhole so the pump inside the tank should last a lot longer. The pump should be drawing fewer amps because it is only charging a pressure tank that actually sits below it, instead of the pump having to lift water 130' or so AND providing pressure.

One of my other acquaintances here has the same setup, but he has a little Gould shallow well centrifugal pump sitting on the outside of his volume tank.