greybeard

Well-known member

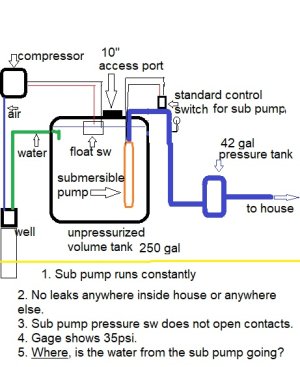

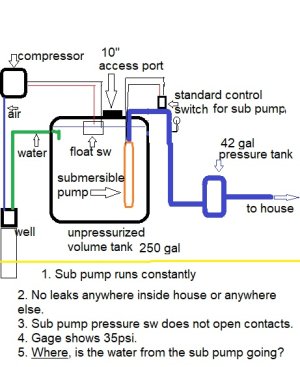

The young couple near me has a water well that uses a little compressor to lift water out of the well bore. I'm familiar with how the down hole part works but they have a volume tank the well empties into and inside the tank, is a submersible pump that supplies water to a little pressure tank. Float valve inside the storage tank cuts the compressor off and on as it should.

That sub pump inside the volume tank tho, runs all the time. Been that way evidently, for months and their elec bill is thru the roof.

I haven't really looked at it closely, but my first thought was the little squareD pressure switch that controls the sub pump was bad, but my next question, was where the heck is the water going the sub pump is pumping?

Is there a popoff valve inside those volume storage tanks and the sub pump is just recirculating the same water?

That sub pump inside the volume tank tho, runs all the time. Been that way evidently, for months and their elec bill is thru the roof.

I haven't really looked at it closely, but my first thought was the little squareD pressure switch that controls the sub pump was bad, but my next question, was where the heck is the water going the sub pump is pumping?

Is there a popoff valve inside those volume storage tanks and the sub pump is just recirculating the same water?